Supply chain complications and bottlenecks are threatening to disrupt the holiday shopping season. At Hobby Lobby, an empty shelf is awaiting a restock in the midst of a holiday sale. Photos by Connor Hart

Every holiday season, owners of Tropic Aire Patio Gallery in West Columbia transform the store into Santa’s Closet, a one-stop shop for Christmas trees, lights and décor.

This year, redecorating the store on Charleston Highway has looked a little different than in the past. Supply chain complications have caused shipments to be late and decorations, once plentiful, to be in low supply.

Santa’s Closet typically begins getting shipments for the holiday season towards the end of the summer, according to Duke Singleton, who co-owns the store with his wife, Judy. This year, he said the first shipments didn’t arrive until Oct. 29, just two days before the store opened on Nov. 1.

“It was certainly a busy weekend,” Singleton said. “And we didn’t even get everything, there’s more on its way.”

Bottlenecks and disruptions in the global supply chain are continuing to impede commercial stocking heading into the holiday season. Holiday items, such as artificial Christmas trees, are in high demand and short supply, threatening to cause problems for last-minute shoppers.

“I’m thinking the holiday season will be a bit of a mess,” Carrie Queenan, a clinical professor at the University of South Carolina’s Darla Moore School of Business, said. Queenan teaches in the Department of Management Science, which studies operations and supply chains.

The ongoing COVID-19 pandemic exacerbated supply chain complications, but is only one of the many factors contributing to them, Queenan said. Severe weather, a global labor shortage and the globalization of the supply chain have all had significant impacts.

Severe weather and natural disasters oftentimes have drastic effects on the retail industry. In March, strong winds caused a cargo ship to block the Suez Canal, creating a logjam of container ships in the canal and disruptions in the supply chain for weeks.

Many workers lost or left their jobs during the pandemic due to a variety of factors, including illness, the responsibility of homeschooling children or caring for home-bound elders and discontent with their employment. Furthermore, major manufacturing areas of Southeast Asia only recently saw a decrease in outbreaks of coronavirus, and are still experiencing high shipping prices, labor shortages and outbreaks of COVID-19.

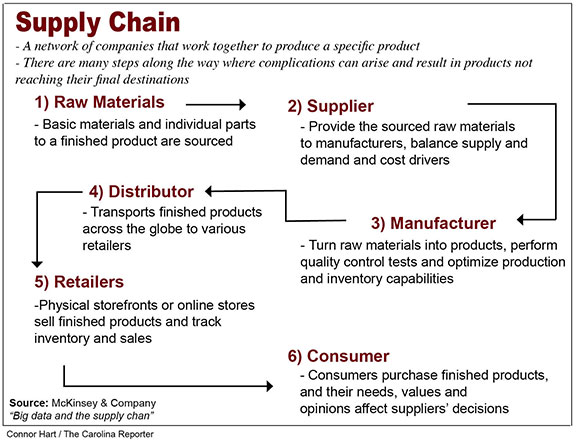

The globalization of the supply chain has many implications as well, both positive and negative. “Companies are so interconnected,” Queenan said. “That’s what helps get us great products, but it also makes complications more severe when they arise.”

A globalized supply chain helps to maximize the efficiency of product output; however, it can make the supply chain inflexible to changes and less resilient.

Many companies cluster all of their factories together in one geographic location –for example, Southeast Asia– where they can produce products cheaply and efficiently, then rely on shipping and transportation to move the products around the world. This practice works well, but problems arise when a geographic area is affected by weather, disaster, labor shortages and/or inflated shipping costs.

Duke Singleton has seen all these impacts first-hand. He said his shipping prices this year were about $21,000 – more than a 400% increase from last year when shipping prices were just under $5,000.

Singleton said he hasn’t seen an increase in consumer shopping, but also said he didn’t expect to this early in the season.

“They’ve been telling everyone to buy early, but I think a lot of people are still going to wait until after Thanksgiving. That’s what we normally see,” Singleton said.

Queenan recommended against waiting until the last minute to buy Christmas decorations or shop for gifts: Buy early, expect delays, support smaller businesses that are less affected by disruptions and embrace nontraditional gifts, she said.

In the short term, Queenan said to expect to see fewer products and less choices on the shelves this holiday season.

Additionally, although artificial Christmas trees might be hard to come by, Christmas tree farms are largely not impacted.

“Our farm is not affected by supply chain management or any of the shipping containers that are stuck off the coast,” a representative from Bear Creek Christmas Tree Farm, located in Chapin, wrote in an email.

Santa’s Closet, located on Charleston Highway in West Columbia, South Carolina, didn’t receive its first shipment of artificial Christmas trees until Oct. 29, only days before the store was set to open. The store still hasn’t received all its inventory.

The prices of artificial Christmas trees sold at Santa’s Closet vary drastically. Smaller trees cost a few hundred dollars, while the largest trees sell for upwards of $1,000.

Hobby Lobby is running promotions on Christmas decorations, despite the global shortage of inventory.

Artificial greenery is stocked at Hobby Lobby as well; however, supply chain experts still recommend customers shop early this holiday season because of consumer demand.